Breed

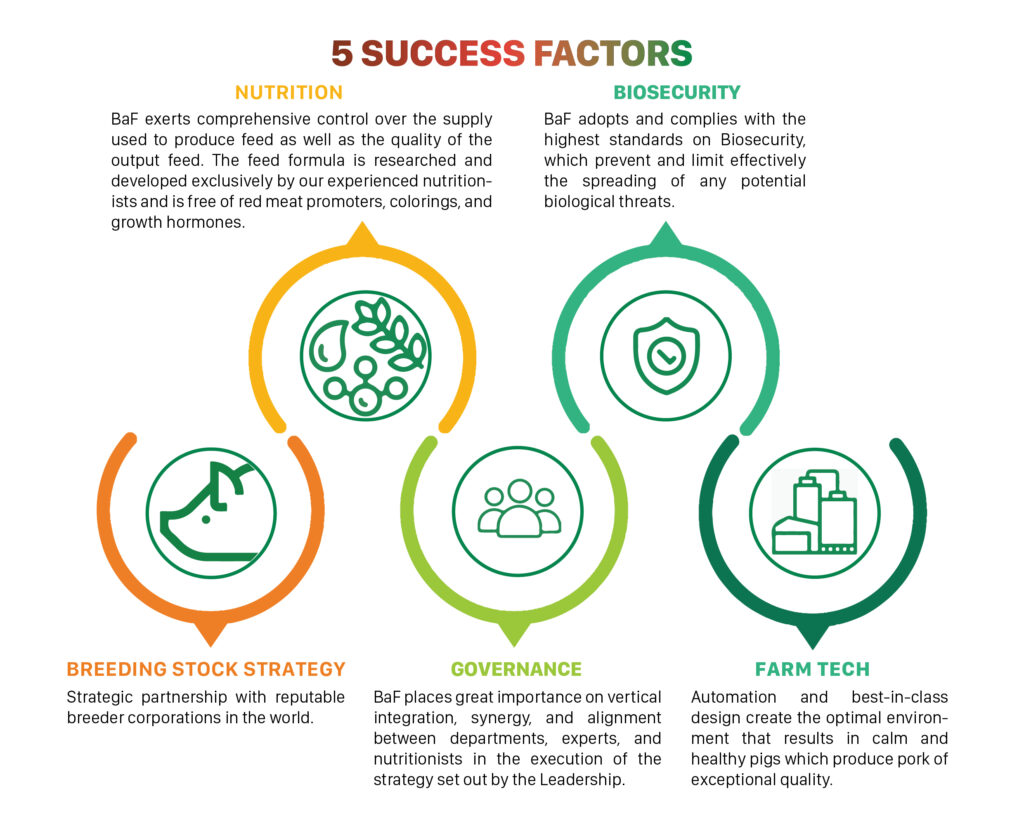

BAF forms strategic partnerships with reputable breeder corporations around the world to select healthy, disease-free, wrong-breeding pigs specially adapted to Vietnam’s weather. This is the number 1 choice for BAF to develop our premium pig products in Vietnam.

Breeding Value Chain

Farm

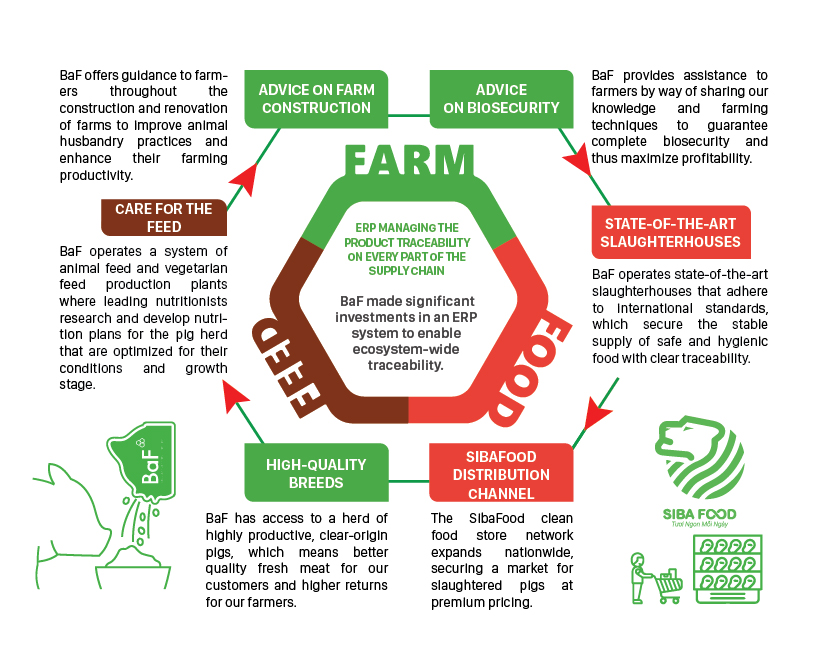

BAF Farm system is located away from residential areas and other farms. Optimum farm capacity, suitable farm temperature, biosecurity, resulting a high productivity and reduced costs due to the significant reduction in operating costs – electricity, water, maintenance, medicine and labors.

The new barn model is modernized with equipment and technology transferred from European and United States corporations.

The factory uses prefabricated houses to increase the use time. The barn equipment is 100% zinc dipped. High strength woven barn floor Mac up to 300 – 350, large mold helps the pigs always stay on the dry floor. The automatic thermal induction cooling system ensures the temperature is always uniform and stable, suitable for each type of pig, increasing the reproductive success rate in farrowing sows, bringing great economic benefits. The automatic feeding system is supplied from the central bran silo into each pigsty, setting the required amount of feed for each type of pig so that the animals can eat according to their needs and preferences.

Waste treatment process

With cutting-edge biotechnology adopted, BAF’s wastewater treatment system is up to the highest standards of “Class A” output water usable in daily settings

In addition, BAF targets building a circular agribusiness, proven by its efforts in recycling livestock wastes and by-products to product bio-organic, micro-organic, and mineral-organic fertilizers to replace inorganic fertilizers; contributing in the worldwide trends of reducing decarbonization and fighting climate change impacts.

Biosecurity is thoroughly controlled from the outside. All vehicles such as pig import and export, manure export, bran supply, etc. are thoroughly disinfected outside the farm and are not allowed inside the farm. People entering the camp from outside are disinfected and isolated for 2-3 days in a separate isolation house; Before entering the production area, they are disinfected with 2 layers.

Up to now, BAF has owned a system of 29 sow and hog farms. Tay Ninh is becoming the “capital” of the company in terms of the number and scale of high-tech pig farms; besides farms in other provinces such as Phu Yen, Nghe An, Thanh Hoa, Binh Thuan, Dak Lak, Kon Tum, Binh Duong, Binh Phuoc…